Challenges

The whole petroleum industrial system starts from wellhead and ends with the refine system. Between wellhead and refine factory is the distributed system such as pump station and pipeline. Operating environments of this industry are full of explode-able materials which may cause tremendous damages, no matter at which part of production processes.

Oil wellhead process

Automated oil tank monitoring system is one of the most important elements in oil wellhead process. This system combines with data transferring, video recording, and voice, which requires huge bandwidth, real-time reaction, and reliable durability.

Oil transmission

Oil is transmitted via pipelines and pump stations. In order to ensure high and uniform flow of oil, pump stations are needed at regular intervals and pipelines must be under control. For example, to keep the pressure in the pipeline at 50 bar pressure, managers must monitor the status continuously.

Oil refining process

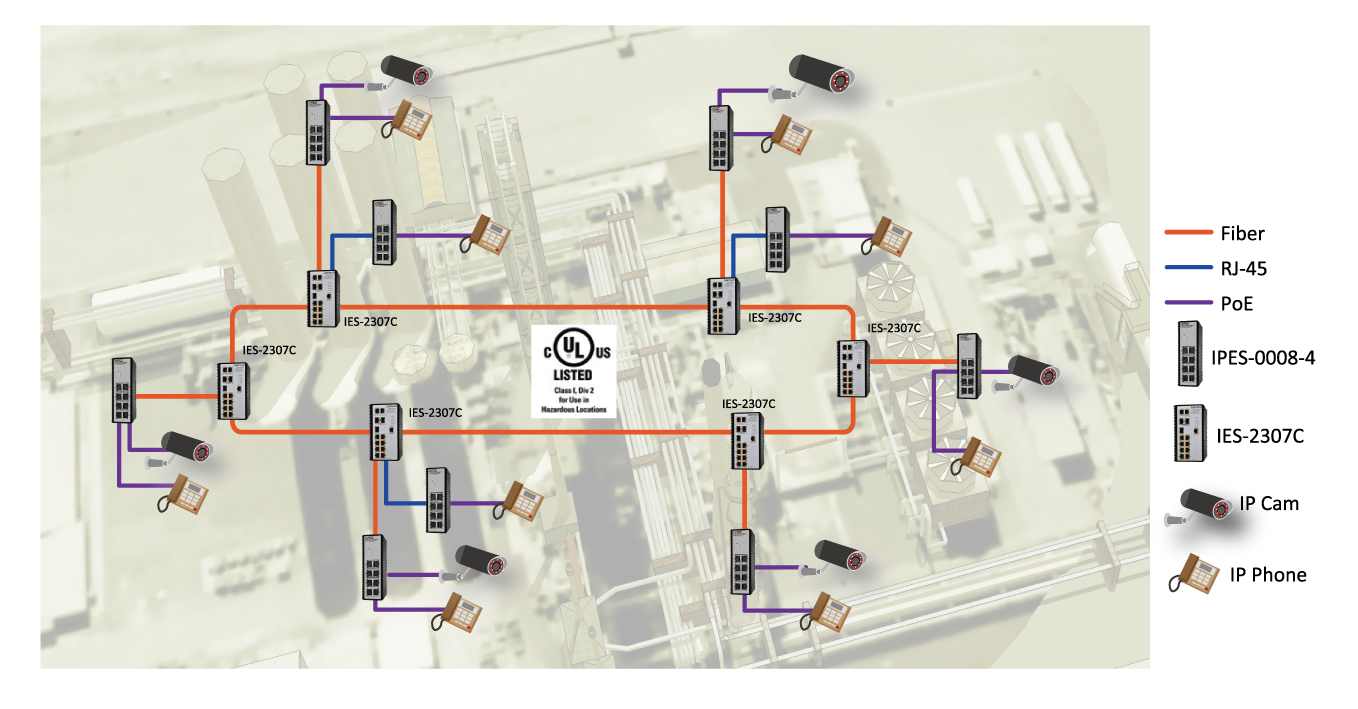

It is consist of several complicated and a large variety of equipments/ devices and need to be deployed by distributed control system (DCS). DCS systems allow the entire system of controllers to be connected by networks for communication and monitoring.

Our Solution

A well-functioned monitor and control system is able to manage remotely, reducing the needs of human visits for maintenance. Oil fields are wildly distributed around the world. Since the oil field may be located in the desert, under the sea, or in the polar zone, the Industrial network must cover wide operating temperature to work properly in these harsh environments. The -E models of Lantech products can be used in extreme environments with an operating temperature range of -40°C to 75°C.

Since oil is flammable and easily to explode, network devices must have different standards to meet with all kinds of hazardous condition. The Lantech products have passed UL Class I Division II for Group A, B, C and D hazardous location, which is a safety certification especially suitable for petroleum industries. With UL Class I Division II approval, the Lantech products can be implemented in hazardous or explosive condition without accelerating the damage.

Product Selection

2020 © Lantech Communications Global, Inc. ALL Rights Reserved. Privacy Policy | Terms of Service